Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

Workplace safety is a critical concern across industries, and one often-overlooked aspect is the role of electrical wiring. Proper selection of electrical wires is fundamental in preventing accidents, ensuring operational efficiency, and maintaining compliance with safety regulations. Electrical wires are not just conduits for electricity; they are lifelines that connect power sources to equipment and ensure that workplaces remain safe for employees. Choosing the wrong wire can result in fire hazards, electric shocks, equipment damage, and costly downtime.

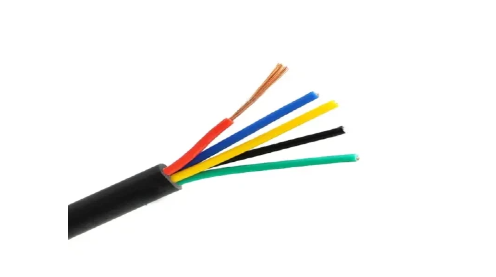

Electrical wire is a conductor designed to transport electricity from a source to an end-use device. The performance of the wire depends on factors such as the conductor material, insulation type, wire gauge, and the environment in which it operates. In workplaces, wires must meet strict safety standards to handle varying loads, resist environmental factors, and minimize risks associated with electrical hazards.

Copper Wires: Copper is the most widely used conductor due to its excellent electrical conductivity, flexibility, and durability. It allows for lower resistance, reducing heat buildup and the risk of fire.

Aluminum Wires: Aluminum is lighter and cost-effective but has lower conductivity compared to copper. Special care is needed during installation to avoid loose connections, which can cause overheating and arcing.

Wire gauge determines the amount of current a wire can safely carry. Undersized wires can overheat, leading to insulation failure, sparks, or even electrical fires. Choosing the correct gauge according to load requirements is essential for workplace safety.

Electrical wires are coated with insulation to protect against electric shocks, short circuits, and environmental exposure. Common types include:

PVC (Polyvinyl Chloride): Suitable for general indoor use; resistant to moisture and abrasion.

XLPE (Cross-linked Polyethylene): Handles higher temperatures and voltage, ideal for industrial environments.

Rubber Insulation: Flexible and heat-resistant; commonly used in portable equipment and machinery.

Selecting the correct electrical wire is critical for maintaining workplace safety. Improper wire choice can result in fire hazards, electric shocks, equipment failures, and even fatalities. By understanding the safety implications, businesses can make informed decisions to protect both employees and equipment.

One of the most significant risks associated with incorrect electrical wiring is fire. Electrical fires often occur due to overloaded circuits, short circuits, or overheating wires. For example, if a wire is undersized for the electrical load it carries, it can heat up excessively, causing the insulation to melt and potentially ignite nearby materials.

Using wires with the appropriate gauge, high-quality insulation, and suitable conductor materials significantly reduces the risk of fire. Copper wires, known for their superior conductivity, paired with XLPE (cross-linked polyethylene) insulation, are ideal for industrial machinery and high-load environments. XLPE insulation not only resists high temperatures but also prevents electrical leakage, ensuring the system remains safe even under demanding conditions.

Additionally, fire-resistant cables are increasingly used in critical areas such as emergency lighting, alarm systems, and data centers. These cables are designed to maintain circuit integrity even during a fire, providing essential time for evacuation and reducing the potential for catastrophic damage.

Exposed or damaged wires pose a serious risk of electric shock to employees. Even low-voltage circuits can be dangerous if workers accidentally come into contact with live conductors. Properly insulated wires with durable coatings prevent direct contact and reduce the risk of shock.

Color-coded insulation adds another layer of safety by allowing electricians and maintenance personnel to quickly identify live, neutral, and ground wires. This reduces the likelihood of errors during installation, troubleshooting, or repairs. For example, in a factory setting, clearly marked wires help maintenance teams isolate circuits safely, preventing accidental energizing of machinery while performing repairs.

The impact of electrical wire selection extends beyond human safety to equipment performance. Undersized or poor-quality wires can cause voltage drops, leading to inefficient operation or sudden shutdowns. Sensitive machinery, including automated production lines, CNC equipment, and computer-controlled systems, requires stable voltage to operate correctly. Inconsistent power delivery can result in malfunctions, product defects, or even permanent equipment damage.

Using the right wire ensures consistent energy flow, improves operational efficiency, and minimizes costly downtime. In high-demand environments, robust wiring with suitable insulation and proper conductor size protects both equipment and personnel from unexpected hazards.

Workplaces encompass diverse environments, from office buildings to industrial plants, each requiring specific types of electrical wiring to ensure safety and compliance.

NM-B (Non-Metallic Sheathed Cable): Commonly used in office buildings, schools, and residential facilities, NM-B cables consist of multiple insulated conductors enclosed in a protective sheath. They are suitable for indoor applications where mechanical protection is minimal.

THHN/THWN Wires: These single-conductor wires are designed for conduit installations and are ideal for industrial or commercial spaces. They offer heat and moisture resistance, making them suitable for areas with high humidity or elevated temperatures, such as boiler rooms and manufacturing floors.

Armored Cables (AC): Industrial environments often expose wires to mechanical damage from machinery, forklifts, or heavy equipment. Armored cables provide an extra layer of protection, preventing accidental cuts, abrasions, or impacts that could compromise insulation and lead to electrical hazards.

Flexible Cords: Used for portable machinery and temporary setups, flexible cords combine insulation and adaptability. They are essential for environments where equipment is frequently moved or adjusted, such as workshops and assembly lines.

UV-Resistant Wires: In outdoor installations, wires are exposed to direct sunlight, which can degrade insulation over time. UV-resistant cables prevent cracking and maintain performance under prolonged solar exposure.

Fire-Resistant Cables: In high-risk areas such as chemical plants, refineries, or storage facilities, fire-resistant cables maintain critical power supply during emergencies. They ensure continuous operation of alarms, emergency lighting, and evacuation systems, safeguarding both personnel and property.

By selecting the appropriate type of electrical wire for the specific workplace environment, businesses can significantly reduce the risk of accidents, improve equipment reliability, and maintain regulatory compliance.

Workplace environments can greatly influence wire performance and safety. Understanding these factors is crucial when selecting wires.

High-temperature areas, such as manufacturing plants, require wires with heat-resistant insulation to prevent melting or degradation. Conversely, cold environments can make some materials brittle, increasing the risk of cracks and exposure.

In humid or wet workplaces, wires must resist water absorption to prevent short circuits. Corrosion-resistant conductors and moisture-proof insulation improve longevity and reduce safety hazards.

Cables running through areas with heavy foot traffic or moving machinery are subject to abrasion and mechanical damage. Armored or reinforced wires are recommended to prevent exposure of the conductor and maintain safety.

Proper installation complements wire selection in ensuring workplace safety.

Wires should be routed to minimize bending, kinking, or pinching. Sharp bends increase the risk of conductor breakage and insulation damage, while crowded conduits can lead to overheating.

Loose connections are a common source of arcing, sparks, and overheating. Use high-quality terminals, connectors, and proper torque settings to maintain secure and stable connections.

Proper grounding of electrical systems prevents dangerous voltage buildup and protects workers from electric shock. Bonding metal components ensures that stray currents do not pose a risk in case of insulation failure.

Adhering to national and international standards such as NEC (National Electrical Code), IEC, or local building codes ensures wires meet performance requirements and safety benchmarks.

Even high-quality electrical wires require ongoing maintenance to ensure safety.

Visual Inspections: Check for wear, cracks, discoloration, or fraying on insulation. Damaged wires should be replaced immediately.

Thermal Imaging: Detects hotspots caused by loose connections or overloaded circuits before they become hazards.

Load Testing: Ensures that circuits operate within safe current limits.

Documentation: Maintain records of wire specifications, installation dates, and maintenance checks for safety audits and regulatory compliance.

Workplace safety is not only about materials but also about people. Employees and maintenance personnel should be trained to:

Identify potential electrical hazards

Understand wire specifications and limitations

Use protective equipment such as insulated gloves

Follow proper lockout/tagout procedures during repairs

A combination of high-quality wiring and trained personnel significantly reduces the risk of workplace accidents.

Workplace safety relies heavily on the correct selection, installation, and maintenance of electrical wires. Choosing the appropriate conductor material, wire gauge, and insulation type can prevent fire hazards, electric shocks, and equipment failures. Coupled with proper installation practices, environmental considerations, and regular maintenance, high-quality electrical wires form the backbone of a safe and efficient workplace.

For businesses looking for reliable, high-performance electrical wires suitable for diverse industrial and commercial applications, Henan Jinshui Cable Group Co., Ltd. offers a wide range of certified products. With professional technical support and adherence to international safety standards, they help ensure that workplaces remain safe, efficient, and compliant with regulatory requirements. Contacting a trusted supplier like Henan Jinshui Cable Group can significantly reduce safety risks while enhancing operational reliability.