Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

In modern electrical systems, efficiency and safety are paramount. Electrical wires serve as the backbone of any electrical network, carrying current from power sources to devices and appliances. While often overlooked, the quality of electrical wires plays a crucial role in energy performance, reliability, and safety. Substandard wiring can lead to energy loss, overheating, equipment malfunction, and even fire hazards. This article explores how electrical wire quality affects performance, energy efficiency, and long-term system reliability, and provides guidance on selecting and maintaining wires to reduce energy loss.

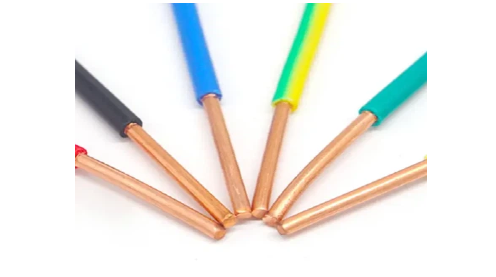

Electrical wires are conductors that transmit electrical energy from one point to another. Typically made from copper or aluminum, they are insulated to prevent short circuits, accidental contact, and energy leakage.

The efficiency of an electrical system depends on several wire characteristics:

Conductivity: High-quality materials allow electrical current to pass with minimal resistance.

Insulation: Proper insulation prevents energy loss and protects against electrical hazards.

Durability: Mechanical strength ensures the wire withstands bending, pressure, and environmental conditions without degradation.

High-quality electrical wires ensure that electrical systems operate efficiently, reduce unnecessary energy loss, and maintain consistent voltage delivery to devices. For industrial facilities, commercial buildings, and residential installations, this translates to both cost savings and safer operation.

Several factors contribute to energy loss in wiring systems. Understanding these factors is essential for selecting wires that optimize energy efficiency, reduce operational costs, and maintain system safety. Energy loss in wires typically manifests as heat generated due to electrical resistance, voltage drops, or leakage currents. Let’s explore the most critical factors in detail.

The conductor material is the most fundamental factor affecting energy efficiency. Copper and aluminum are the most widely used conductors in residential, commercial, and industrial wiring systems. Each has its advantages and limitations:

Copper: Known for its excellent conductivity, copper allows electrical current to flow with minimal resistance. High-purity copper ensures that less energy is dissipated as heat, providing a stable voltage supply for sensitive equipment such as computers, industrial machinery, and HVAC systems. Impurities in copper, however, can increase resistance and energy loss, reducing the overall efficiency of the system.

Aluminum: While aluminum is lighter and generally more cost-effective, its conductivity is about 61% that of copper. To compensate, aluminum wires often need to have a larger cross-sectional area for the same current-carrying capacity. Despite this, aluminum remains a popular choice in high-voltage transmission lines and large-scale electrical installations due to its lower weight and material cost.

For industrial applications, using high-purity, certified copper or appropriately rated aluminum ensures minimal energy loss and prevents overheating or voltage irregularities in sensitive devices.

The thickness, or gauge, of an electrical wire directly affects its resistance. A wire with an insufficient cross-sectional area has higher electrical resistance, which leads to several issues:

Voltage Drop: Thin wires cannot carry large currents efficiently, resulting in reduced voltage at the device end. This can impair the performance of motors, lighting, and electronics.

Heat Generation: High resistance causes energy to be converted to heat, which not only wastes electricity but also risks damage to insulation and surrounding components.

Conversely, choosing the correct wire gauge ensures smooth current flow and minimizes energy loss. For example, a 10 AWG copper wire can safely transmit higher currents over longer distances than a 14 AWG wire, reducing the need for frequent upgrades or replacements. For facilities with extensive wiring networks, selecting the right gauge is a key step in optimizing both energy efficiency and safety.

Insulation materials influence energy performance in several ways. Inferior insulation can deteriorate over time due to heat, moisture, UV exposure, or chemical contact, which leads to leakage currents and wasted energy. High-quality insulation provides:

Dielectric Strength: Prevents current from leaking through the insulation and reduces energy loss.

Heat Resistance: Maintains performance under high temperatures generated by current flow.

Chemical and Environmental Protection: Shields the conductor from corrosion, moisture ingress, and mechanical abrasion.

Modern insulation materials, such as XLPE (cross-linked polyethylene) or Teflon coatings, are engineered for high-performance applications. They maintain energy efficiency over long-term use and reduce maintenance requirements in industrial and outdoor installations.

Even premium-quality wires can underperform if installed improperly. Poor installation practices increase energy loss through:

Loose Connections: Improperly tightened terminals increase resistance at junction points.

Excessive Bending or Twisting: Sharp bends or tangled wires create micro-stress points that elevate resistance.

Mechanical Stress: Cables under tension or compression may degrade insulation or conductor integrity over time.

Organized and professional installation, including proper bending radii, secure terminals, and structured routing, minimizes resistance, prevents hotspots, and ensures long-term energy efficiency. Additionally, properly installed wires reduce maintenance costs, extend system life, and improve overall operational reliability.

Investing in superior electrical wire can significantly enhance performance across residential, commercial, and industrial applications. The benefits extend beyond immediate efficiency gains to long-term cost savings, improved safety, and regulatory compliance.

The primary function of electrical wire is to carry current with minimal energy loss. High-quality wires, typically made from high-purity copper or aluminum, have lower resistivity compared to substandard materials. This means that electricity flows more efficiently, and less energy is dissipated as heat. For instance, in industrial facilities with long electrical runs spanning hundreds of meters, low-resistance copper wires help maintain stable voltage levels, ensuring that machinery operates reliably without excessive energy loss. Similarly, in commercial buildings, high-conductivity wires support energy-efficient lighting and HVAC systems, reducing overall utility consumption.

Selecting the appropriate wire gauge is crucial for minimizing energy loss. Undersized wires increase resistance, resulting in voltage drops and heat generation, which can damage sensitive equipment over time. Conversely, wires with the correct cross-sectional area allow current to flow smoothly, reducing resistance and ensuring energy reaches devices efficiently. While oversized wires may incur a higher initial cost, the investment pays off through lower energy consumption, less heat-related wear, and extended lifespan of electrical components. For example, upgrading from a 14 AWG to a 10 AWG wire in a high-load motor circuit can significantly reduce energy loss and prevent overheating.

Insulation quality directly affects energy efficiency and safety. High-grade insulation materials—such as PVC, XLPE, or Teflon—protect wires from moisture, chemicals, UV radiation, and mechanical stress. Superior insulation prevents leakage currents and energy loss, while also extending the life of the wiring system. In outdoor or industrial environments, durable insulation ensures consistent performance even under extreme temperatures or harsh conditions, reducing the risk of fire hazards and equipment failure.

High-quality electrical wires are more resilient and require less frequent replacement. Consistent performance minimizes downtime, especially in manufacturing plants and large commercial facilities, where interruptions can be costly. Additionally, durable wiring reduces maintenance labor and component replacement expenses. Over the long term, investing in premium wires delivers tangible financial savings while supporting uninterrupted operations.

Superior wires are manufactured to meet international standards such as IEC, UL, and ISO certifications. Compliance ensures that electrical systems not only operate efficiently but also adhere to safety regulations. By using wires that meet these standards, businesses and homeowners reduce the risk of fire hazards, equipment failure, and regulatory penalties. Moreover, certified wires guarantee optimized energy performance, contributing to sustainability goals and energy conservation efforts.

Selecting the right wire requires careful consideration of several factors:

Load Requirements: Calculate the electrical load to determine the appropriate gauge.

Material Choice: Prefer high-purity copper for critical systems; aluminum can be used where weight or cost is a concern.

Environmental Conditions: For outdoor or corrosive environments, choose wires with weather-resistant or chemical-resistant insulation.

Compliance Standards: Ensure wires meet IEC, UL, or local regulatory standards for performance and safety.

Professional Installation: Hire certified electricians to avoid installation-related inefficiencies.

By considering these factors, electrical systems can operate with minimal energy loss, enhanced reliability, and increased safety.

Modern electrical wire technology focuses on reducing energy loss and improving performance:

High-Conductivity Alloys: Advanced copper alloys offer lower resistance and improved thermal performance.

Smart Wiring: Some wires incorporate sensors for monitoring current flow, voltage, and temperature in real-time.

Eco-Friendly Insulation: New insulation materials reduce environmental impact while maintaining efficiency and safety.

Flexible, Lightweight Designs: Cables for industrial and renewable energy applications are designed to minimize resistance while improving handling and installation speed.

These innovations ensure that modern electrical systems not only deliver energy efficiently but also maintain longevity and safety.

Energy loss in electrical systems is often an overlooked problem, yet the choice of electrical wire significantly influences efficiency, safety, and operating costs. By selecting high-quality conductors with proper gauge, insulation, and installation, businesses and homeowners can reduce energy waste, improve equipment performance, and ensure safer operation.

Investing in premium electrical wire is not just about meeting regulatory standards—it’s a strategic decision that saves money, protects infrastructure, and supports sustainability.

For more information on high-quality electrical wire solutions and to explore products designed for superior performance and safety, visit Henan Jinshui Cable Group Co., Ltd.. Their range of professional-grade electrical wires can help you optimize energy efficiency and safeguard your electrical systems.