Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

Electrical wiring is the backbone of modern buildings, enabling lighting, heating, communication systems, and smart technologies to function efficiently and safely. Choosing the right type of electrical wire is crucial for ensuring safety, energy efficiency, and long-term reliability in both residential and commercial structures. With a wide variety of wires available, understanding their properties, applications, and installation considerations is essential for architects, engineers, and builders.

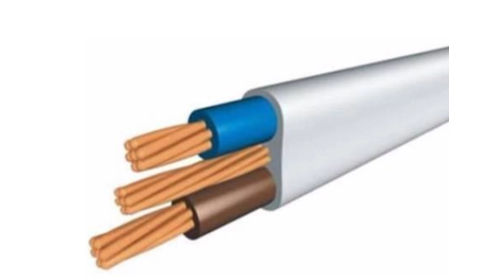

Electrical wire is a conductor designed to carry electricity from a power source to devices, lighting, outlets, and other components within a building. Typically made of copper or aluminum, wires are coated with insulating materials to prevent short circuits, electric shocks, and fire hazards.

Modern buildings often incorporate multiple wire types for different purposes, including:

Power transmission

Low-voltage communication

Data and network connectivity

Specialty systems like fire alarms and renewable energy systems

Selecting the correct wire involves considering current load, voltage rating, insulation type, flexibility, and environmental conditions.

Modern buildings rely on a variety of electrical wires to meet the diverse demands of power distribution, communication, safety, and automation systems. Understanding the characteristics, advantages, and limitations of different wire types is essential for architects, engineers, and electricians to ensure safe, efficient, and durable installations. Here is a detailed look at the most commonly used types of electrical wire.

Also known as Romex, NM cable is widely used in residential construction due to its affordability and ease of installation. It typically consists of two or more insulated conductors and a bare ground wire, all encased in a plastic sheath.

Applications:

Indoor residential circuits such as lighting, outlets, and small appliances

Dry, protected areas including bedrooms, living rooms, and kitchens

Small renovations or extensions requiring flexible routing

Advantages:

Easy to install and bend around corners without conduit

Cost-effective and readily available

Provides adequate safety for standard household voltages

Considerations:

Not suitable for outdoor or wet environments

Must follow local building codes

Requires careful handling to avoid damaging the sheath

NM cable is a go-to choice for residential projects, offering simplicity, flexibility, and reliability for standard household loads.

Armored or metal-clad cables feature a metallic sheath, typically aluminum or steel, providing mechanical protection and fire resistance.

Applications:

Commercial and industrial buildings with exposed wiring

Areas prone to physical damage or rodent interference

Outdoor or semi-exposed locations with weather-resistant insulation

Advantages:

Durable and resistant to mechanical impacts

Can be installed without additional conduit

Resistant to rodents, abrasion, and minor damage

Considerations:

Heavier and less flexible than NM cable

Requires special connectors for termination

Higher installation costs due to labor and material

Armored cables are widely used in offices, shopping centers, and warehouses where durability and safety are priorities.

Thermoplastic High Heat-Resistant Nylon-Coated (THHN) and THWN wires are common in commercial and industrial environments. They withstand high temperatures, moisture, and chemical exposure, typically installed in conduits.

Applications:

Conduit wiring in offices, factories, and commercial buildings

HVAC systems, lighting circuits, and motor connections

Areas with high temperatures or occasional wet conditions

Advantages:

Heat-resistant up to 90°C (194°F)

Moisture and chemical resistant

Long-lasting with stable insulation under stress

Considerations:

Must be installed inside conduit

Requires careful stripping to avoid insulation damage

Less flexible than NM cable, making tight routing challenging

THHN/THWN wires are crucial for high-performance commercial installations where safety and code compliance are essential.

Low-voltage wires operate at 50 volts or less, primarily used for communication, security, and decorative systems.

Applications:

Security cameras, alarm systems, and access control

Intercoms and smart home devices

Landscape lighting and indoor decorative systems

Advantages:

Flexible and easy to route through walls and conduits

Safe to handle, minimal shock risk

Cost-effective for low-power applications

Considerations:

Not suitable for high-power circuits

Must follow manufacturer guidelines for distance and current

Low-voltage wiring is increasingly important in smart buildings, supporting IoT integration and automated systems.

Coaxial cables consist of a central conductor, insulation, metallic shield, and outer jacket, designed for high-frequency data transmission.

Applications:

Cable TV and broadband internet

CCTV and security systems

Structured cabling in residential and commercial buildings

Advantages:

Supports high-frequency signals with minimal interference

Durable and resistant to physical damage

Can transmit over long distances without significant loss

Considerations:

Less flexible than NM or low-voltage wires

Requires proper connectors and precise installation

Coaxial cables remain standard for reliable entertainment and security systems in homes and offices.

Fiber optic cables transmit data as light through glass or plastic fibers, ideal for high-speed networks.

Applications:

Enterprise and data networks

High-speed internet for residential and commercial buildings

Smart building automation and IoT systems

Advantages:

Extremely high bandwidth and fast transmission

Immune to electromagnetic interference

Supports long-distance data transfer

Considerations:

More expensive than copper cables

Requires specialized installation and handling

Fiber optic wiring is key for modern smart buildings, supporting data-heavy applications like cloud services and video streaming.

While copper is the most common conductor, aluminum wire is used in large-scale residential and commercial circuits due to its light weight and cost-effectiveness.

Applications:

Service entrance and main distribution conductors

High-capacity branch circuits in commercial buildings

Industrial feeders with high current requirements

Advantages:

Lightweight, reducing load on conduits and panels

Cost-effective alternative to copper

Good conductivity when properly sized

Considerations:

Requires anti-oxidant compounds at connections to prevent corrosion

Must use connectors rated for aluminum

Thermal expansion differences with copper connections need management

Aluminum wiring is often chosen for utility systems and large commercial projects where weight and cost are key considerations.

Selecting the right electrical wire for modern buildings is crucial to ensure safety, efficiency, and long-term reliability. Several key factors must be carefully considered to match the wire type with the intended application and environmental conditions.

One of the most important considerations is the load capacity of the wire. This includes both the current (amperage) and voltage requirements of the system. Using a wire with insufficient capacity can lead to overheating, insulation damage, fire hazards, and eventual system failure. For example, a 15-amp NM cable may be sufficient for standard lighting circuits but inadequate for high-power appliances or HVAC systems. Properly calculating the load ensures that the wire can handle peak demands safely.

The installation environment plays a significant role in wire selection. Wires installed outdoors, in wet areas, or near chemicals require special insulation, such as THWN or armored cables, to resist moisture, corrosion, and physical damage. Indoor installations in dry, protected areas may use simpler NM or low-voltage wires. Understanding environmental conditions helps prevent premature failure and reduces maintenance costs.

Some installations require wires to bend around corners, pass through conduits, or navigate tight spaces. Flexible wires, like NM or low-voltage types, are easier to route and handle in these scenarios. In contrast, armored cables or high-temperature wires may be less flexible, requiring additional planning for bends and conduit placement.

Compliance with local building codes, the National Electrical Code (NEC), and international standards is mandatory. Proper installation according to these regulations ensures safety, protects against liability, and may be required for insurance coverage. Following standards also guarantees that the electrical system performs reliably under expected conditions.

In homes, electrical wires power lighting, appliances, HVAC systems, and smart devices. NM cables are often used in interior circuits, while THHN or THWN wires run through conduits for high-load circuits like air conditioners and kitchen appliances.

Offices, shopping centers, and hospitals require a mix of high-voltage and low-voltage wiring. Armored cables, THHN/THWN, and fiber optic cables ensure safety, reliability, and high-speed data transmission.

Factories and warehouses demand wiring that can withstand heat, mechanical stress, and exposure to chemicals. Armored cables, aluminum conductors, and specialized insulated wires are commonly used in these environments.

With the rise of IoT and automation, modern buildings incorporate electrical wiring for sensors, smart lighting, automated HVAC, and data networks. Fiber optic cables and low-voltage wires are integral to these systems, enabling energy efficiency and real-time monitoring.

Choosing the right type of electrical wire is fundamental to the safety, efficiency, and performance of modern buildings. From NM cables in residential circuits to fiber optic cables in smart buildings, understanding the specific applications and characteristics of each wire type allows architects, engineers, and contractors to design reliable electrical systems.

For high-quality electrical wire solutions suitable for a variety of applications—from residential to industrial and commercial—Henan Jinshui Cable Group Co., Ltd. offers a comprehensive range of products that meet international standards for safety and performance. Their expertise and quality assurance make them a trusted partner for projects requiring durable, efficient, and compliant electrical wiring solutions.

To explore their full range of electrical wire products and get guidance on selecting the right solutions for your building projects, consider visiting Henan Jinshui Cable Group Co., Ltd. Their team can provide professional advice, technical specifications, and support for all your wiring needs.