Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

Electrical wiring is an integral part of modern infrastructure, powering homes, businesses, and industrial facilities. Despite its utility, electrical wire poses significant safety risks if not handled properly. Electric shocks, short circuits, and fires are some of the hazards associated with improper wiring practices. Therefore, understanding and following safety protocols is essential for both professionals and DIY enthusiasts. This article explores the top safety practices when handling electrical wire, emphasizing proper techniques, tools, and precautions.

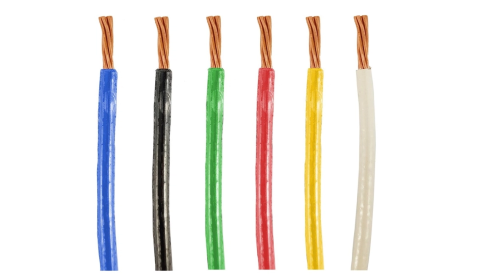

Before diving into safety practices, it is important to understand what electrical wire is and its various types. Electrical wire is a conductor, typically made of copper or aluminum, that carries electric current from one point to another. Insulation, usually made of PVC, rubber, or Teflon, covers the wire to prevent accidental contact and ensure safety.

Solid Wire: Single, solid strand of metal. It is durable and less prone to damage, commonly used in permanent wiring installations.

Stranded Wire: Composed of multiple thin strands twisted together. It is flexible and ideal for applications requiring movement or vibration resistance.

THHN/THWN Wire: Thermoplastic high-heat-resistant wire commonly used in conduit systems for residential and commercial buildings.

Romex/NM Cable: Non-metallic sheathed cable used for interior residential wiring.

Understanding the type of wire you are working with is crucial, as different wires have specific installation requirements and safety considerations.

One of the most fundamental safety practices when handling electrical wire is the use of personal protective equipment (PPE). PPE is designed to minimize the risk of injury from electrical shock, burns, or cuts, and it forms the first line of defense for anyone working with or around electricity. Choosing the right PPE depends on the type of electrical work, voltage levels, and environmental conditions. Proper use of PPE not only protects workers but also ensures compliance with safety regulations and reduces workplace accidents.

Insulated gloves are essential for protecting hands from electric shocks and burns. They are available in various classes, each rated for a specific voltage range. It is crucial to select gloves that match the voltage of the system being worked on. Regular inspection for cuts, cracks, or wear is necessary, as damaged gloves can compromise safety.

Electrical work can involve sparks, flying debris, or accidental splashes of insulation chemicals. Safety goggles shield the eyes from these hazards, preventing injuries such as burns, punctures, or irritation. Opt for goggles that provide a secure fit and meet industry safety standards.

For high-voltage or industrial applications, flame-resistant clothing is critical. It protects against burns caused by electrical arcs or sparks, and helps minimize the severity of injuries in case of accidents.

Electrical hazards can extend to the feet, especially in wet or conductive environments. Safety shoes with non-conductive soles prevent accidental shocks and provide additional protection against heavy objects, punctures, or slips.

Using the correct tools and ensuring they are in good condition is another key safety practice. Faulty tools or improper use can lead to serious accidents.

Always use insulated pliers, wire cutters, and screwdrivers when working with live wires. Insulated tools prevent accidental current flow through your body.

Voltage testers, multimeters, and continuity testers should be used to verify that wires are de-energized before handling. Testing devices should be regularly calibrated to ensure accuracy.

Cable strippers allow precise removal of insulation without damaging the wire. Damaged conductors can cause overheating, short circuits, or electrical fires.

When working at heights, use non-conductive ladders made of fiberglass or wood. Metal ladders can conduct electricity, increasing the risk of shock.

A well-prepared work area reduces hazards and makes electrical installations safer and more efficient.

Before handling electrical wire, always turn off the power at the breaker panel. Lockout/tagout procedures ensure that no one accidentally restores power while work is in progress.

Remove clutter, tools, or water from the area to prevent slips, trips, and accidental contact with live wires.

Adequate lighting is essential for precision work, helping prevent mistakes such as cutting the wrong wire or improper connections.

In industrial or shared spaces, use warning signs or barriers to alert others of ongoing electrical work. This prevents accidental interference and improves overall safety.

Proper handling of electrical wire is crucial to prevent damage to the wire and ensure long-term safety.

Electrical wires are vulnerable to cuts, abrasions, and crushing. Always:

Avoid dragging wires over sharp edges.

Use conduit or protective channels in high-traffic areas.

Do not bend wires sharply; maintain minimum bending radius to prevent conductor damage.

When stripping insulation, only remove the necessary length of insulation. Excessive stripping exposes the conductor unnecessarily, increasing the risk of shorts or accidental contact. Terminate wires using proper connectors, ensuring a secure and conductive connection.

Always follow local and national electrical codes (e.g., NEC in the USA) for installation. Codes dictate wire gauge, insulation type, routing, grounding, and termination requirements to maintain safety and compliance.

Do not exceed the current rating of wires. Overloading can cause overheating and fire hazards. Properly calculate the load and use wires with adequate ampacity.

Ensure proper grounding of electrical systems. Grounding provides a safe path for fault current, preventing electric shock or equipment damage. Bonding all metallic parts reduces the risk of voltage differences that could lead to shocks.

While it’s best practice to work with de-energized circuits, certain situations require working on live wires. Extreme caution and specialized equipment are necessary.

When working on live circuits, ensure all tools are insulated and PPE is rated for the system’s voltage.

Keep hands and conductive materials away from live parts. Use tools with long insulated handles to maintain a safe distance.

Regularly test the circuit for voltage presence before touching any wire. Non-contact voltage detectors can help identify live wires safely.

Always have a plan in place for electrical emergencies. Know the location of emergency shut-off switches, first aid kits, and be trained in CPR and electrical shock response.

Proper storage and handling of wire spools prevent damage and maintain their integrity.

Electrical wire should be stored in dry, temperature-controlled environments. Moisture can degrade insulation, while extreme heat or cold can make it brittle.

Keep wires on spools or racks to prevent tangling and kinks. Avoid dragging wires on the ground, which can cause abrasions.

Clearly label wires by type, gauge, and voltage rating. Proper organization ensures that the correct wire is used for each application, reducing errors.

Regular maintenance and inspection of electrical wiring are vital for safety.

Look for insulation cracks, discoloration, frayed ends, and loose connections. Replace any damaged wires immediately.

Use infrared thermography to detect overheating wires or connections, which may indicate overload or poor termination.

Perform periodic continuity, insulation resistance, and voltage drop tests to ensure system integrity. Testing helps identify potential hazards before they escalate into accidents.

Even the best materials and tools cannot guarantee safety without proper knowledge. Training personnel on electrical safety is crucial.

Encourage electricians and maintenance staff to complete certified training programs covering electrical safety, code compliance, and emergency response.

Regular safety meetings reinforce best practices and provide a forum to discuss recent incidents, lessons learned, and updated procedures.

For non-professional users, education is key. Simple safety guidelines—such as turning off power before handling wires and using insulated tools—can prevent accidents at home.

Advancements in wire technology and safety tools are making electrical work safer than ever.

New insulation materials improve fire resistance, reducing the risk of electrical fires.

Circuit breakers with real-time monitoring and remote alerts provide added safety by detecting overloads and faults immediately.

Modern cable trays, conduits, and raceways help organize wires efficiently, minimizing hazards and making inspection easier.

Handling electrical wire safely is crucial for preventing injuries, fires, and equipment damage. Key practices include:

Using the correct PPE and insulated tools.

Properly preparing the work area.

Following correct installation, termination, and grounding procedures.

Storing, transporting, and maintaining wires appropriately.

Ensuring ongoing training and awareness.

By following these practices, professionals and DIY enthusiasts alike can minimize risks and maintain safe electrical systems.

For those seeking high-quality electrical wire and professional guidance, Henan Jinshui Cable Group Co., Ltd. offers a wide range of cables for residential, commercial, and industrial applications. Their products are designed with safety, durability, and performance in mind. To learn more about their offerings or consult on your next project, you can contact Henan Jinshui Cable Group directly. Partnering with an experienced supplier ensures your wiring projects meet both safety and quality standards, providing peace of mind for every installation.